(Figure 1: Patina on a Shigefusa kitaeji yo-gyuto.)

Japanese knives, renowned for their superior cutting performance and timeless beauty, are much more than culinary tools. They symbolize a masterful interplay between skillful craftsmanship and centuries-old tradition, achieving a balance that gives them their unique charm. Two popular types of these treasured tools, stainless steel and carbon steel knives, offer distinct features appealing to different users.

Japanese stainless steel knives are appreciated for their resistance to corrosion, ensuring ease of maintenance. On the other hand, carbon steel knives hold a special allure, lauded for their exceptional sharpness and the fascinating ability to develop a patina over time. This intriguing characteristic not only enhances the aesthetic appeal of the knives but also tells a story about their history and journey. In the following sections, we will delve deeper into this remarkable feature, providing a comprehensive understanding of patina in the realm of Japanese carbon steel knives.

I. Understanding Patina

(Figure 2: Greenish patina, known as "verdigris", on a dragon statue found in a Japanese temple. Image source: Vincent384 via Shutterstock.)

Patina is a natural, superficial discoloration that forms on the surface of certain metals over time. This colorful layer acts as a protective seal, offering good rust prevention.

Derived from the Italian word for a shallow deposit layer on a surface, 'patina' has roots in the Latin term 'patĭna,' which denotes a pan or shallow dish. When used figuratively, 'patina' can extend to include various signs of aging, such as fading or darkening, often considered intrinsic or inevitable aspects of an object. Patina develops through a process called 'patination,' and any artifact or work of art embellished with patina is described as 'patinated.'

The development of patina results from oxidation, corrosion, or chemical reactions between the material and its environment. These interactions often result in a thin, colored layer on the surface, enhancing its distinctive appearance. The composition and look of patina depend on the specific material and environmental conditions. For instance, copper develops a greenish patina known as verdigris, while bronze can acquire various shades of brown, green, or blue.

Patina is highly esteemed, particularly when found on antique objects, artwork, or architectural elements, as it can enhance their aesthetic appeal and historical significance. An example is the dragon statue in a Japanese temple shown in Figure 2, which over time has developed a green patina, or verdigris, that adds to its striking appearance.

II. Patina and Japanese Carbon Steel Knives

(Figure 3: Full patina on an iron clad AS gyuto forged by Yoshikazu Tanaka.)

The patina on Japanese carbon steel knives is more than just an appealing trait. It's a record of the knife's life, reflecting its use over time and the variety of meals it has helped to create.

Each interaction with food contributes to the formation of the patina, leaving behind unique marks that tell the story of its culinary journey. The patina is an ongoing transformation, always changing with the knife's use, reflecting the wide array of ingredients it has encountered.

Apart from its symbolic value, the patina also serves a practical function by protecting the blade from corrosion. This naturally formed shield helps the knife last longer, standing up to the challenges of daily use in any kitchen.

No two patinas are alike. This adds a unique elegance to each knife, differentiating it from others. The patina is a reflection of the craftsmanship involved in the knife's creation and the tangible experiences it's been a part of.

In essence, the patina on a Japanese carbon steel knife blends art, function, and history into a single feature. It's not just a knife's characteristic; it's a living record of culinary adventures, capturing the relationship between a chef and their primary tool.

III. Natural and Forced Patina

(Figure 4: Patina on two knives with different cladding and patination: natural patina on a Kiyoshi Kato gyuto with iron cladding and forced patina on a Watanabe Pro gyuto with stainless cladding.)

Patina can form naturally over time, bearing witness to the blade's journey with its owner. Each slice and chop, each contact with different ingredients, contributes to the unique pattern and color of the patina. As the knife cuts through various foods, the carbon steel reacts with moisture and the acids present in those foods. Acidic ingredients like onions and the proteins in meat can expedite the patina formation process, leaving unique patterns and colors on the blade that reflect its culinary history.

For those wanting to speed up the patina formation, there's an option known as 'forced patina'. This involves applying reactive substances, such as coffee or mustard, directly to the blade's surface. These substances accelerate the oxidation process that forms a patina. For example, you could soak the knife in a cup of hot, strong coffee for a few minutes, or apply a thin layer of mustard to the blade and leave it for a similar period of time. This exposure to reactive substances speeds up the natural process that would otherwise occur over a longer period of use.

After the treatment, the knife is rinsed and dried, revealing a newly formed patina that ranges in color from dark grey to almost black, depending on the type of substance used and the duration of exposure.

The Watanabe Pro gyuto shown in Figure 4, for example, was soaked in hot, strong coffee. Don't worry - the high temperature will not destroy the temper of the core steel. The exposure to heat isn't enough to alter the hardened steel's temper, ensuring that the knife's performance isn't compromised in the pursuit of accelerated patina formation.

IV. Why Carbon Steel Knives Form Patina

(Figure 5: The Kei Kobayashi bunka knife (top) with SG2 core, a stainless steel with 15% chromium, offers corrosion resistance. The Teruyasu Fujiwara santoku (bottom) features an aogami super core, a carbon steel with just 0.4% chromium, making it prone to patination.)

In order to truly understand why patina forms on some knife blades and not on others, it's important to grasp the basic composition of steel. Steel, at its core, is made up of iron and carbon, with small amounts of other elements, such as manganese, chromium, and vanadium. These alloying elements are added to improve the properties of the steel, such as its strength, toughness, and corrosion resistance.

The chromium content, specifically its percentage by mass, determines whether a knife develops a patina or not. While molybdenum and nitrogen also contribute to corrosion resistance in knives, chromium is the main alloying element responsible for this.

Stainless steel, which contains a significant amount of chromium—usually at least 13%—is renowned for its corrosion resistance, which largely prevents the formation of patina. It is this 13% chromium that makes stainless steel “stainless”. However, it's important to note that "stainless" doesn't mean 'stain-never’. Even stainless steel can develop a faint patina when exposed to certain acidic or corrosive substances.

In contrast, carbon steel knives, which either lack chromium or contain only trace amounts, are more prone to oxidation, a process that spurs the development of patina. The most common Japanese carbon steels are Hitachi’s white (shirogami) and blue (aogami) steels. Semi-stainless steels like SKD and HAP40, which contain around 4-5% chromium, also develop a patina, albeit at a more gradual pace. Despite the chromium content, they often bear a resemblance to carbon steels in their tendency to form a patina.

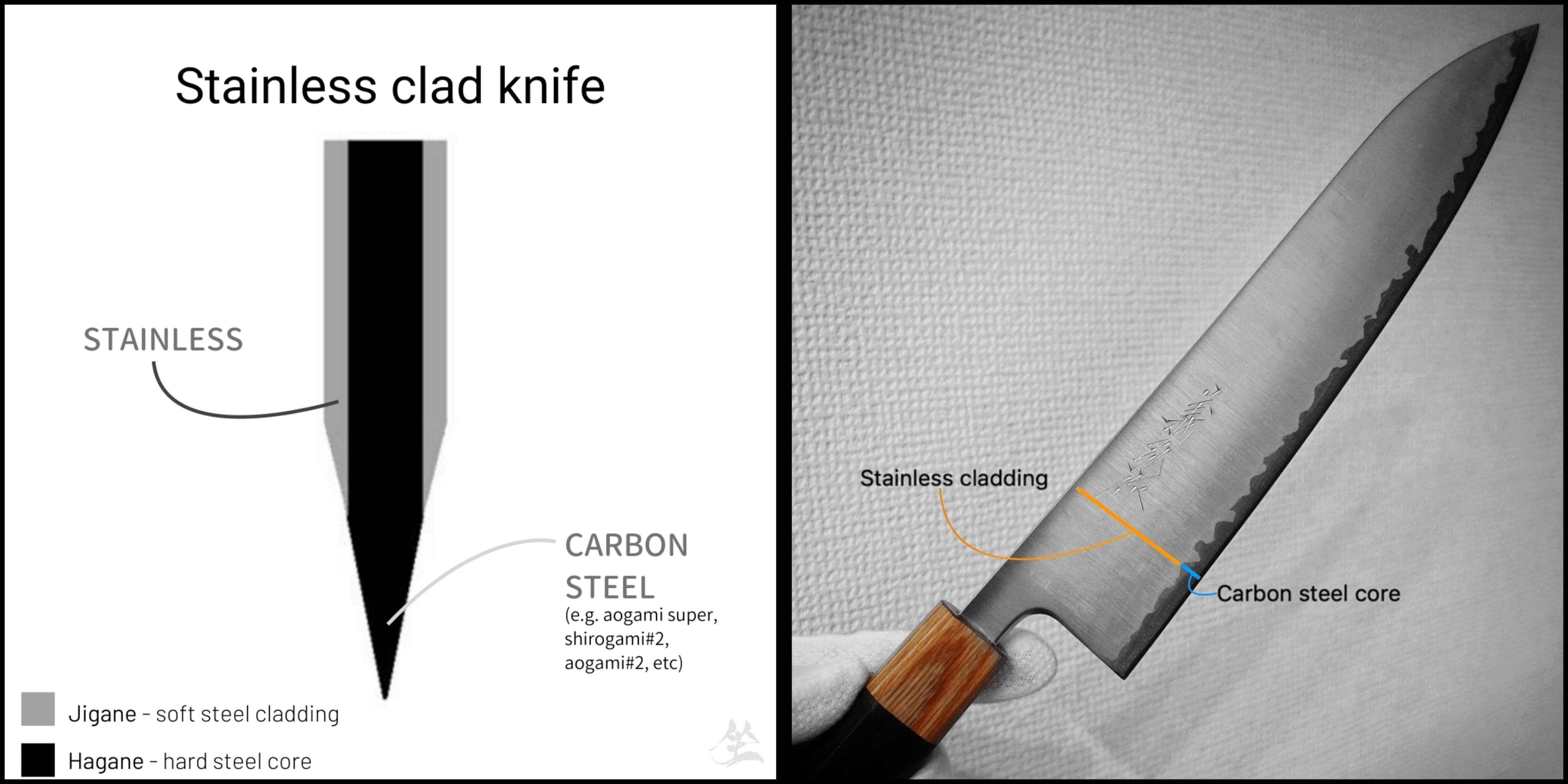

V. Stainless Clad Carbon Steel Knives: Best of Both Worlds

(Figure 6: A cross-section of a stainless clad carbon knife and a Yoshihiro aogami super stainless clad gyuto.)

Understanding the reservations some users may have regarding the higher maintenance demands of carbon steel, Japanese knife makers introduced an ingenious solution: stainless clad carbon steel knives. This innovative construction integrates both materials, offering users a 'best of both worlds' experience.

In these knives, the carbon steel forms the core, or the 'cutting edge,' which is then enveloped or 'clad' in stainless steel. This construction ensures that the majority of the carbon steel is shielded from direct exposure to moisture and air, reducing the possibility of rusting or corrosion.

The outer layer, or the 'jacket,' of stainless steel imparts a degree of corrosion resistance akin to that of a fully stainless steel knife. This protective layer takes on the brunt of any environmental exposure and bears the responsibility of corrosion resistance. Consequently, the knife owner gets to enjoy the carbon core steel without the usual high-maintenance demands of a monosteel carbon or iron clad knife.

For those who appreciate the beauty of patina development but seek a lower maintenance knife, stainless-clad carbon steel knives present an attractive solution. This construction offers an ideal blend of features: the superior sharpness of carbon steel, the reduced maintenance of stainless steel, and the development of a beautiful patina over the core steel.

VI. Iron Clad, Monosteel Carbon, and Honyaki: Embracing the Full Patina Process

(Figure 7: Patina on various Japanese carbon steel knives. From L-R: Ashi honyaki gyuto, Yoshikazu Tanaka AS, Zahocho special - Miyazaki damascus, Masahiro VC, Shigefusa kurouchi.)

While stainless clad carbon steel knives offer a balance between maintenance ease and the unique appeal of patina, for most knife enthusiasts, the allure of fully embracing the patina process is simply irresistible. This is where iron clad, monosteel carbon, and honyaki knives come into the picture.

Iron clad knives comprise a hard steel core encased in a soft iron cladding, creating a contrast to stainless clad knives that use stainless steel for the outer layer. The entire blade of an iron clad knife is predisposed to patina development, offering a deep dive into the patina journey. This results in a blade that is rich in character, bearing a visual testament to its usage and evolution over time.

Monosteel carbon knives, on the other hand, are crafted from a single piece of carbon steel, without any cladding. As a result, the entire blade of a monosteel carbon knife can develop a patina. An example of a favorite monosteel carbon knife is the Masahiro VC carbon gyuto shown in Figure 7.

Taking the single material concept to its peak are honyaki knives. Honyaki, meaning "true-forged", represent the highest level of craftsmanship; only a few skilled craftsmen in Japan can make them. These craftsmen employ techniques similar to those of traditional nihonto (Japanese sword) where a single piece of steel is differentially heat-treated. The resulting blade has a resilient spine and a hard, sharp edge.

VII. Reactivity of Carbon Steel and Patina Formation

(Figure 8: Patina on a Masahiro VC gyuto, a monosteel carbon knife.)

The captivating allure of a well-developed patina is undeniable. However, the significance of patina extends far beyond just the visual aesthetics. It serves as a compelling indicator of a carbon steel knife's reduced reactivity. This reduction is particularly noteworthy when the knife comes into contact with acidic ingredients like tomatoes and onions, which are known to react with bare carbon steel.

During initial use, a carbon steel knife might interact with these acidic food items, potentially resulting in minor discoloration and an unusual metallic taste. However, it's crucial to note that this is not a common occurrence and is mainly seen with lower-grade carbon steel knives, particularly those made from SK carbon steels. SK carbon steels, due to their higher impurity content, exhibit increased reactivity, thereby being more likely to interact with acidic food items.

Despite these potential initial interactions, don't let this deter you from using carbon steel knives. With regular use, a carbon steel knife develops a stable patina - a beautiful, protective layer that reduces the blade's reactivity over time. This patina is not just visually appealing but acts as an indicator of the knife's maturing state.

So, while the initial concern regarding reactivity can be prevalent with specific lower-end carbon steels, it's not a widespread issue for the majority of carbon steels.

VIII. Caring for Your Patina

The care and maintenance of a patina on your Japanese knife follow the same principles as caring for any carbon steel knife. This routine contributes to preserving the knife's unique character and longevity.

Cleaning your knife needs to be both gentle and thorough. Keep in mind that a dishwasher is detrimental to your knife. The high heat and aggressive detergents inside a dishwasher can strip away the patina and compromise the blade's integrity. Instead, opt for a hand wash using a mild detergent, effectively removing any food residues and helping to preserve the patina.

Equally important is to rinse and dry your knife immediately after use. While the patina does provide a layer of protection against rust, it isn't an absolute barrier. If you leave your knife wet or uncleaned, you risk corrosion over time. Immediate drying after washing prevents water spots from forming and helps maintain the patina's integrity.

Proper storage also matters in preserving your knife's patina. Always keep your knife in a dry environment to protect it from unnecessary exposure to moisture. A knife block or a magnetic strip is an excellent choice for safe and appropriate storage, ensuring your knife's patina stays well protected.

Maintaining the patina on your knife is akin to the usual care given to a carbon steel knife. The routine remains: clean, dry, and store properly. This diligent practice not only prevents rust but also preserves the unique narrative that the patina brings to the knife's journey with its owner. Thus, each time you use your knife, you're adding to the unfolding story of a well-seasoned culinary tool.

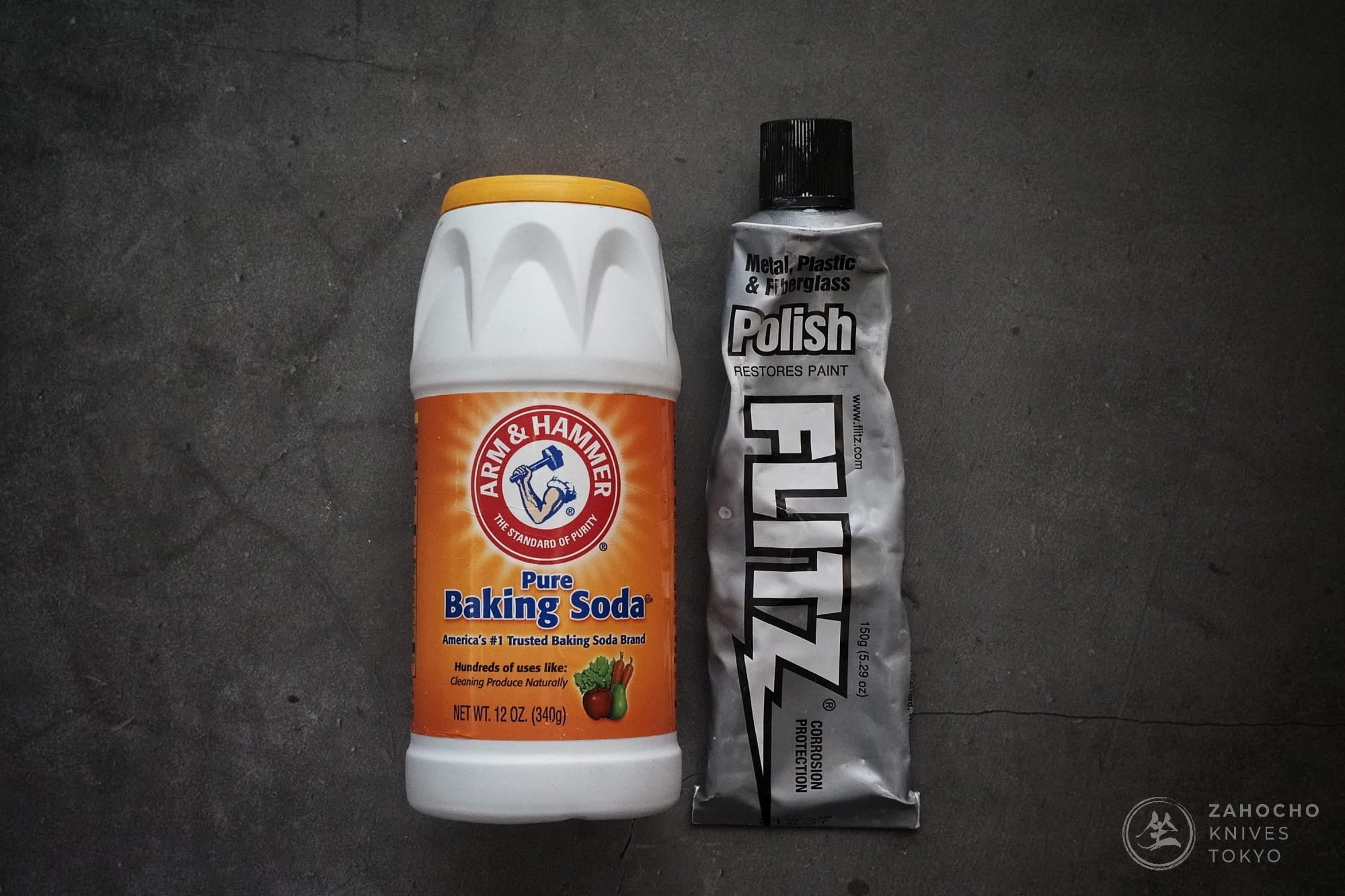

IX. Patina Reset

(Figure 9: Baking soda and Flitz for patina as well as rust removal.)

While patina imparts an alluring character to your knife, there may be instances where you might prefer to return your knife to its original state. The reasons for this can be manifold - perhaps you wish to start the patination journey afresh, or maybe you want to remove a patina that you feel detracts from the blade's appearance. Whatever the reason, the process of 'resetting' the patina is straightforward, and with careful application, can ensure your knife is returned to its original gleaming condition.

An effective and simple method to remove patina is to use baking soda paste. Mix baking soda with a small amount of water to create a thick paste. This paste can be applied to the knife's blade, gently rubbed onto the surface, and then rinsed off.

However, if the patina is stubborn, a product like Flitz can be used. This non-toxic and non-abrasive product is effective in removing patina and can also be used to remove any rust that may have formed.

Conclusion

(Figure 10: Fresh patina on a Shigefusa kitaeji wa-gyuto.)

The formation and development of patina on a Japanese carbon steel knife is both a practical and aesthetic facet of this culinary tool. It is a protective shield against corrosion, ensuring your knife remains in peak condition while also acting as a visual diary of the knife's history and usage.

Whether naturally formed or forced, a patina is not merely a surface change. It's the blade's adaptive response to its environment and usage, making it a reflection of its journey. Knowledge of this process deepens your understanding and connection to these expertly crafted tools, making the experience of using a Japanese carbon steel knife richer and more personal.

A patina is an integral part of a carbon steel knife's identity. It enhances its character while adding an element of individuality to each blade. Through understanding and caring for your knife's patina, you're able to ensure your culinary instrument continues to serve you well, maintaining its integrity and telling its unique story with every use.