Quick Navigation:

Japanese and Western knives differ fundamentally in steel hardness, which affects everything from sharpness to maintenance. Japanese knives use harder steel (60-65 HRC) that holds a razor-sharp edge longer, while Western knives use softer steel (54-58 HRC) that's more durable for tough tasks.

In this article, we'll compare Japanese and Western knives across key factors: steel composition, edge maintenance, blade geometry, weight, aesthetics, and craftsmanship approaches. Understanding these differences will help you choose the right knife for your kitchen.

Quick Comparison: Japanese vs Western Knives

| Feature | Japanese Knives | Western Knives |

|---|---|---|

| Steel Hardness | 60-65 HRC (harder) | 54-58 HRC (softer) |

| Edge Retention | Holds edge longer | Requires more frequent sharpening |

| Blade Geometry | Thinner profile | Thicker, more robust |

| Best For | Precision cutting, delicate tasks | Tough tasks, hard ingredients |

| Edge Maintenance | Whetstone recommended | Honing rod or whetstone |

| Weight | Lightweight and nimble | Heavier with more leverage |

| Aesthetics | Artisanal, decorative finishes | Functional, straightforward |

| Price Range | Varies widely, often handcrafted | Generally more affordable |

Steel Hardness and Composition

One of the primary differences between Japanese and Western knives is the type of steel used in their blades. Japanese knives are typically crafted from harder steel, which allows them to maintain a razor-sharp edge for longer periods. Both Japanese carbon and stainless steel knives can have HRC ratings ranging from 60 to 65. For instance, Aogami Super is a popular high-HRC carbon steel that typically ranges from 63 to 65. Japanese stainless steels, such as SG2 from Hitachi, can achieve HRC ratings ranging from 62 to 64, making them some of the hardest stainless steel knives available. However, it's worth noting that there are some Japanese steels that are slightly tougher but are still hard compared to western standards, such as the budget steel SK carbon or the stainless steel, AUS8 by Aichi Steel Corporation.

In contrast, Western knives are often made with softer steel, which makes them more durable but require more frequent sharpening to maintain a sharp edge. They typically have HRC ratings ranging from 54 to 58, which is considered relatively soft compared to Japanese knives. This feature makes Western knives more suitable for demanding tasks such as cutting hard nuts or semi-frozen foods, earning them a fond nickname among enthusiasts: "beater knives."

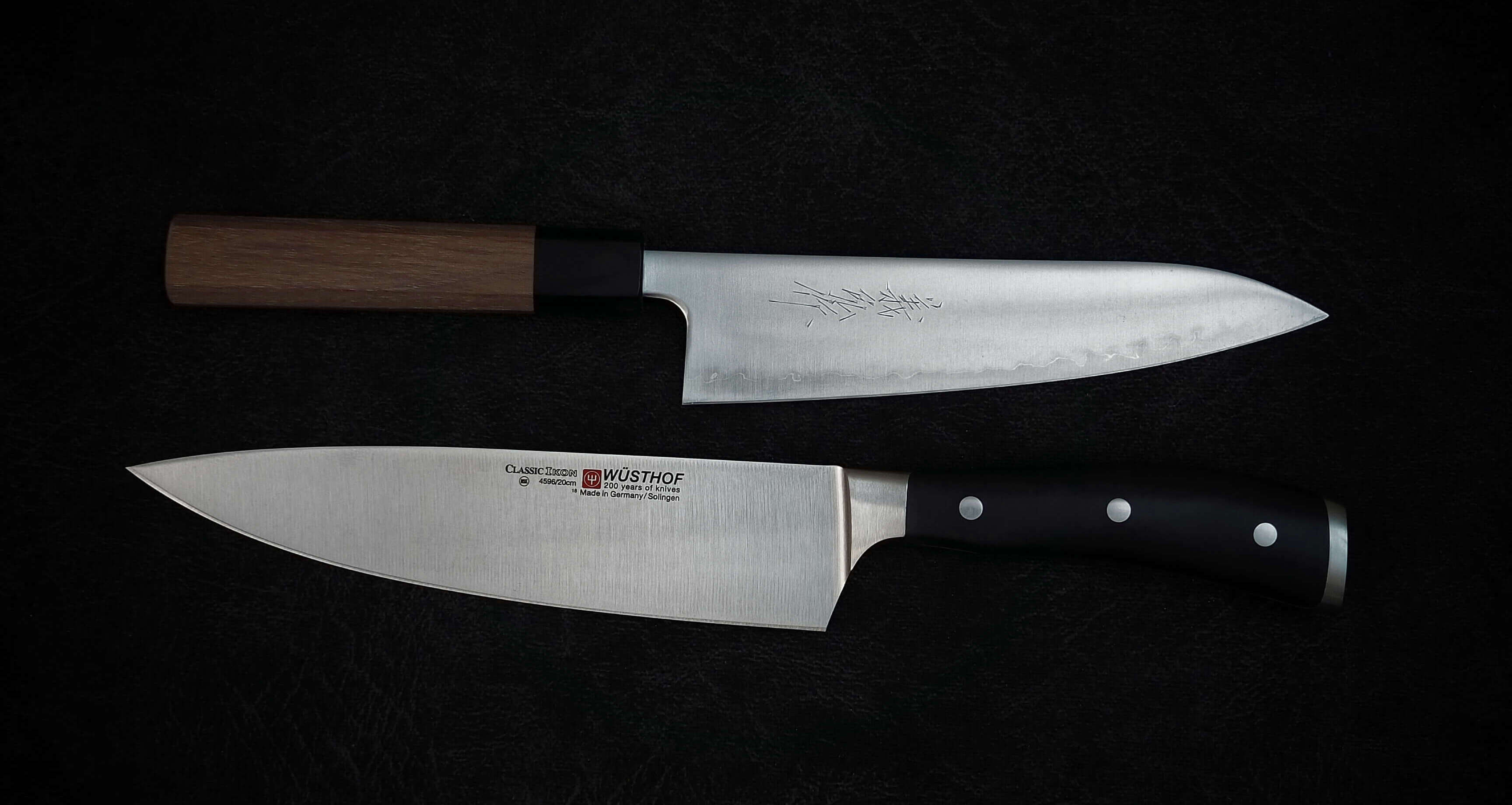

One of the most popular steels used in Western knives is 1.4116 or X55CrMo14, commonly found in brands like Victorinox. The Wusthof Classic Ikon chef's knife featured above is made of X50CrMoV15 steel, which consists of 0.5% carbon, 15% chromium (for corrosion resistance), and smaller amounts of molybdenum and vanadium. In contrast, Japanese knife steels typically contain 1.0% carbon or more.

Why carbon content matters: Carbon is the primary hardening element in all knife steels. Western knives use lower carbon content (around 0.5%), which makes the steel tougher and durable. Japanese knives use higher carbon content (1.0% or more), which makes the steel harder and capable of holding a sharper edge longer. The tradeoff: harder steel requires more careful handling to prevent chipping.

Edge Maintenance

Another important factor affected by the differences in steel is the edge maintenance of Japanese and Western knives. Because of their harder steel, Japanese knives require special care when it comes to sharpening and touch-ups. It is recommended to use a whetstone to sharpen or touch-up the edge of Japanese knives, as honing rods can cause damage, especially in the hands of a beginner.

On the other hand, Western knives are more forgiving when it comes to edge maintenance due to their softer steel. They can be touched up using honing rods to re-align the edge, providing a temporary sharp edge. It's worth noting that both types of knives benefit from regular sharpening on a whetstone.

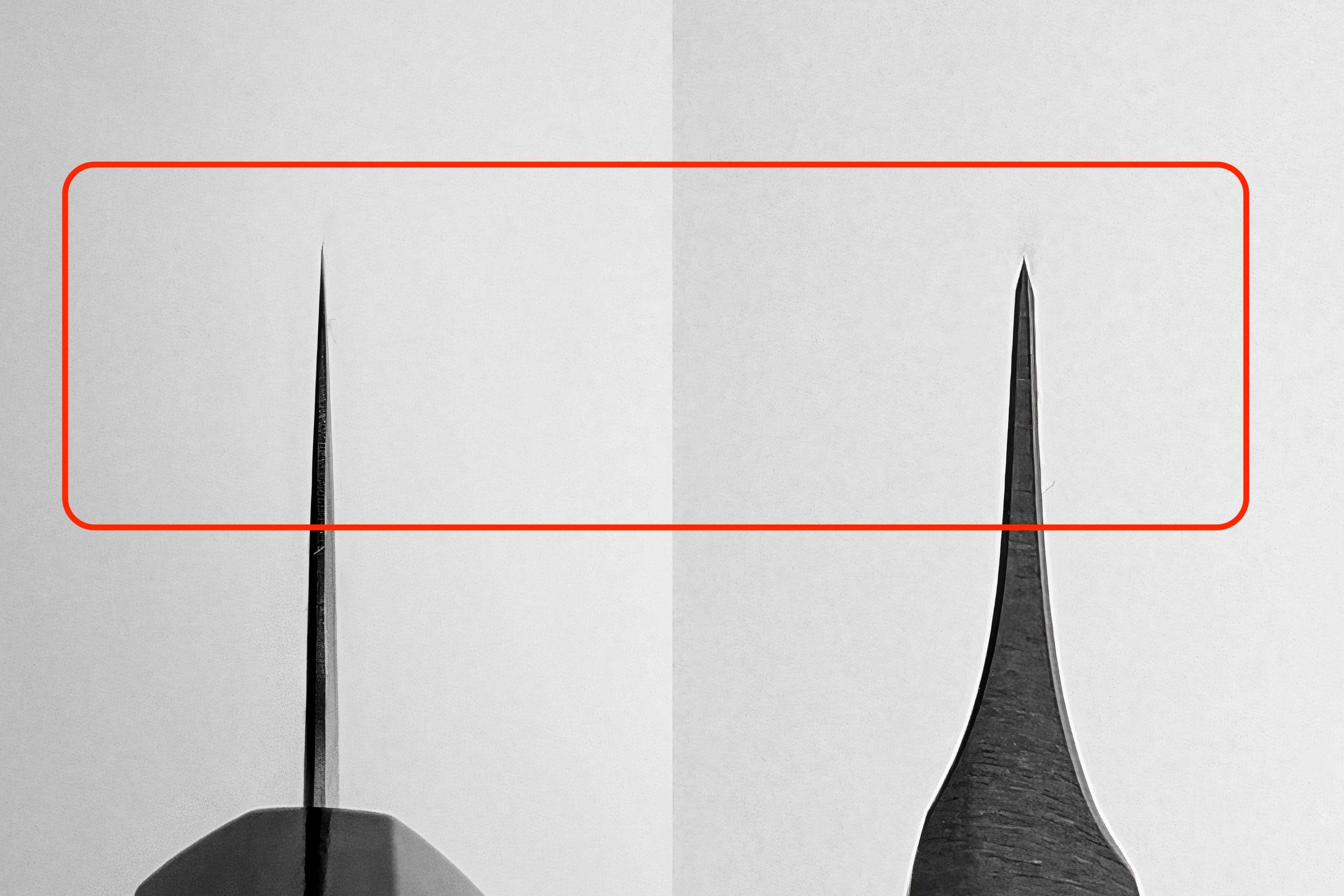

Cross-Sectional Geometry

Japanese knives are known for their thinner cross-sectional profile compared to Western knives, which are typically thicker. The thin profile of Japanese knives allows for more precise and effortless cuts through various ingredients. In general, a knife with a thinner cross-sectional geometry results in better and smoother cutting performance. Thinner blades require less force to complete a cut, and they are less likely to wedge. This is especially evident when cutting dense ingredients like carrots or potatoes. A thinner blade will glide through these ingredients with ease, while a thicker blade will require more force and may produce uneven cuts. The thicker cross-sectional geometry of Western knives offers more durability and strength, making them suitable for demanding and robust cutting tasks.

Weight and Handling

Japanese knives are known for their lightweight design, making them more agile and easier to handle for precise cutting tasks. This reduced weight also leads to less hand fatigue during prolonged use, allowing for longer cutting sessions.

Conversely, Western knives tend to be heavier, which provides more leverage and makes them better suited for tougher cutting tasks. The additional weight of a Western knife can help to provide the necessary force and stability required for such tasks. However, this added weight can make them less nimble and harder to control for more delicate cutting tasks.

Despite their heavier weight, there are some Western knives that are designed to be relatively lightweight, such as the Wusthof Pro series. These knives are specifically designed for use in the foodservice industry, where chefs may need to use a knife for extended periods without experiencing fatigue.

Aesthetics and Design

Japanese knives offer an artisanal and traditional feel that sets them apart from Western knives. They are renowned for their exceptional craftsmanship and meticulous attention to detail, which is reflected in their aesthetic appeal. Japanese knives come in various finishes like migaki, damascus, kurouchi, tsuchime, and nashiji, each offering a unique and distinct look. The handles are also often made with great care, using natural materials like wood, which adds to the overall appearance of the knife.

In contrast, Western knives tend to have a more functional and straightforward appearance. While some Western knives may have decorative elements, they are generally less ornate than their Japanese counterparts. The handles of Western knives are often designed for practicality, with materials like plastic, rubber, or synthetic composites used for their durability and ease of maintenance.

Traditional and Modern Approaches to Cutlery

Japanese and Western knives also differ in their approaches to craftsmanship. Japanese knives have a unique and handcrafted charm that distinguishes them from their Western counterparts. They are made using traditional methods that have been passed down for generations, with designs and concepts that are heavily influenced by Japanese sword-making techniques. The forging process of Japanese knives is meticulous and time-consuming. Each knife is often handcrafted by skilled artisans who employ traditional techniques.

In the Sakai region of Japan, which is known for producing some of the best knives in the world, there are different master craftsmen for each stage of the knife-making process. Typically, there is a bladesmith who forges the blade and a sharpener/polisher who grinds and sharpens the knife to a razor-sharp edge. This approach to knife-making ensures that each knife is crafted with the utmost care and attention, resulting in a product that is not only functional but also a work of art.

In contrast, Western knives are often mass-produced with a focus on consistency and affordability and a more utilitarian design. While Western knives may not have the same traditional and artisanal feel as Japanese knives, they are still crafted with precision and attention to detail. They undergo a rigorous process of heat treatment, grinding, and honing to ensure that they are sharp and durable.

Which Knife Should You Choose?

For pure cutting performance and edge retention, Japanese knives are superior. Their harder steel and thinner geometry make them ideal for 90% of kitchen tasks: slicing vegetables, portioning boneless proteins, and precision work. The key limitation is to avoid hard ingredients like bones, or frozen foods, which can cause chipping.

Western knives serve as excellent "beater knives" for the remaining 10%: breaking down whole chickens, cutting through bones, or handling semi-frozen ingredients. Their softer, tougher steel can handle these demanding tasks without damage.

If you're starting out, begin with a Japanese knife from our Essential Series for everyday cutting tasks, or browse our full collection to see what's currently available. Add an affordable Western chef's knife later for tougher tasks where durability matters more than cutting performance.

About the author: Fred M. trained at Tokyo Sushi Academy and worked as a sushi chef before starting Zahocho Knives in 2019. Based in Japan, he sources knives from renowned knife-making regions like Sakai and Sanjo, working with blacksmiths like Yoshikazu Tanaka, Satoshi Nakagawa, and Kisuke Manaka.